Nguyễn Văn Thành, KP9 , Chánh Phú Hòa, Bến Cát, Bình Dương

Sửa Máy CNC GSK Syntec Của Trung Quốc Và Đài Loan Dịch Vụ Nâng Cấp Máy Phay Tiện CNC Bình Dương

HỖ TRỢ TRỰC TUYẾN

Kinh Doanh: 0937029193

Giờ Làm Việc: 8h đến 18h từ thứ 2 đến thứ 7.

Danh mục: Sửa chữa máy CNC

Mô tả

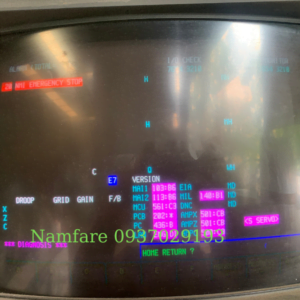

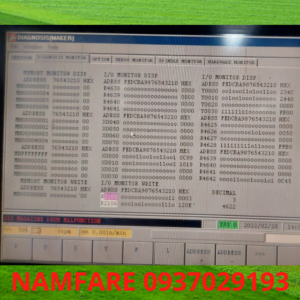

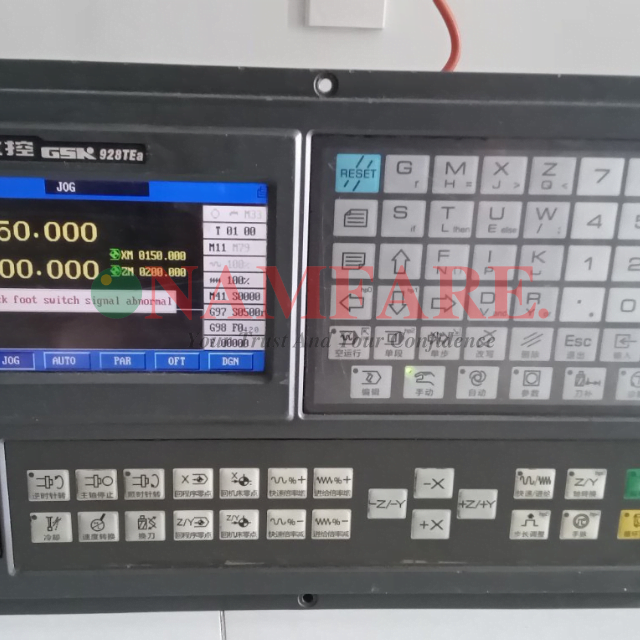

Namfare chúng tôi chuyên sửa chữa các hệ điều khiển CNC GSK, cải tạo nâng cấp hệ thống phần điện cho máy CNC phay và tiện, chúng tôi đã thực hiện nhiều dự tại các khu công nghiệp tại Bình Dương, Bình Phước, Đồng Nai và Sài Gòn. Hệ điều khiển của hãng GSK sử dụng cho máy tiện: Loại GSK 980TDb 980Te 980TD… – Ưu điểm của dòng hệ điều khiển này của hãng GSK là đơn giản, dễ vận hành và sử dụng và cài đặt nhanh dễ thay thế các linh kiện và dễ sửa chữa, linh kiện có sẵn.

Ngoài ra chúng tôi còn sửa chữa máy CNC tất cả các hãng, hệ điều khiển như: Fanuc, Mitsubishi, Amada, Mazak, Siemens, Okuma, Yasnac, Toshiba, Hyundai, Hitachi, LS, DMG Mori Seiki, GSK, Syntec và các hãng Trung Quốc Đài Loan. Chúng tôi còn nhận sửa chữa Bộ điều khiển máy CNC – Kiểm tra và sửa lỗi Bộ điều khiển CNC SYNTEC 6MA – Dịch vụ chuyên Sửa chữa Bộ điều khiển CPU máy CNC các hãng và có bộ điều khiển thay thế.

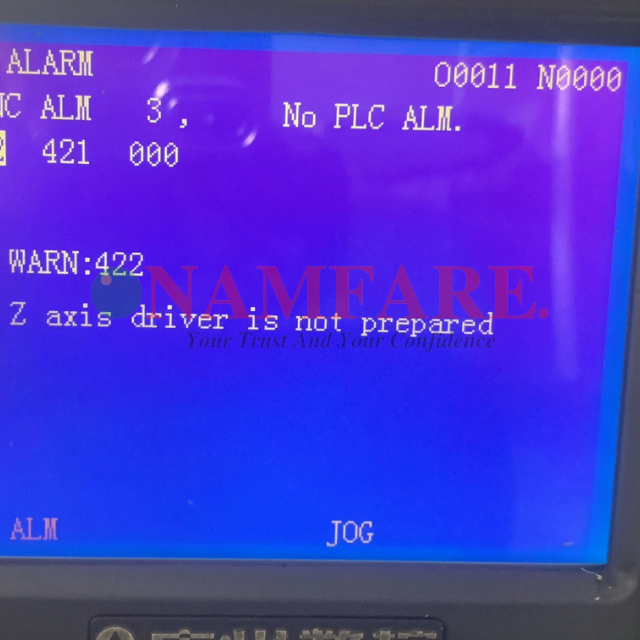

000 Emergent stop alarm and ESP open circuit

001 Called programs do not exist or cannot be opened

002 G command values are negative or with decimals

003 Characters are less than 2 or more than 11 for one word

004 Address error (address is A~Z)

005 Illegal command value

006 Block numbers are negative or with decimals

007 Illegal G commands

008 Execute G96 when the spindle analog voltage control is invalid

009 Command movement distance when G commands in group 00 and 01

are not input and there are invalid commands in group 01

010 There are the same addresses in one block

011 There are more than 40 words in one block

012 Command values exceed their valid range or command addresses which

cannot be omitted is omitted

013 Input S commands except for S00~S99 when the spindle analog voltage

control is invalid

014 G commands in group 00, 01 and 12 cannot be in the same one block

015 Execute M commands for spindle automatic gear shifting when the

spindle analog voltage control is invalid

016 Tool offset numbers exceed their valid range(0~32)

017 Tool number exceeds the range of No.084 parameter

018

The data specified by the interpolation command cannot form a correct

curve, or there is no necessary command, or the data exceeds No.154

range

019 The tool group number exceeds the range(1~32)in the tool life

management

020 Cannot execute T command in C tool nose radius compensation, cancel it

024 There is no G11 or G13.1 in the program

025 There is no tool in the current tool group in the tool life management

026 The current tool group has not been defined in the tool life management

027 The tool quantity exceeds 8 in the current tool group in tool life

management

028 The tool life management function is invalid and G10 L3 cannot be used

029 G11 cannot be in front of G10

030 X movement distance isn’t zero in G33

031 There is non-monotony of corresponding coordinates in G71~G73

032 Absolute value of R is more than that of U/2 in G90, G92

033 Absolute value of R is more than that of W in G94

034 There are more than 100 blocks in G70~G73

035 Ns and Nf are reversed each other in G70~G73

Appendix

463

Appendix

No. Content Remark

036 There is no Ns or Nf or they exceed their allowed range in G70~G73

037 There is no Ns or Nf in G70~G73

038 Single infeed exceeds its allowed range in G71 or G72

039 Single tool retraction exceeds its allowed range in G71 or G72

040 Total cutting travel exceeds its allowed range in G73

041 Cycle times is less than 1 or more than 99999 in G73

042 Single tool retraction R(e) exceeds its allowed range in G74 or G75

043 The tool retraction is negative at the end of cutting in G74 or G75

044 X/Z single cutting value exceeds its allowed range in G74 or G75

045 Starting point of cutting taper thread is between thread starting point and

its end point in G76

046 Min. cutting value exceeds its allowed range in G76

047 Finishing allowance exceeds its allowed range in G76

048 Tooth height is less than finishing allowance or 0 in G76

049 Cycle times exceeds its allowed range in G76

050 Chamfer exceeds its allowed range in G76

051 Angle of tool nose exceeds its allowed range in G76

052 X/Z movement distance in G76 is zero

053 There is no specified tooth height P in G76

054 There is no the first cutting depth Q or Q is 0 or Q is not input

055 Call subprograms in G70~G73

056 Ns does not command G00 or G01 in G70~G73

057 X/ Z value is not specified in the first block or the movement is 0 in G71

058 X/ Z value is not specified in the first block or the movement is 0 in G72

059 Z value is 0 or not input in G74

060 Q value is 0 or not input in G74

061 X value is 0 or not input in G75

062 P value is 0 or not input in G75

063 Initial blocks are employed with the forbidden G commands in G70~G73

064 End blocks are employed with the forbidden G commands in G70~G73

065 Execute G70~G73, G07.1, G12.1 in MDI mode

066 The cycle starting point is in the closed area formed by the starting point

and end point of the finishing path

067 Flute quantity is more than 10

068 Starting point coordinates are abnormal when cycle ends and returns to

starting point

069 G76 tool nose angle is more than or equal to thread angle

081 Y cannot feed with X, Z

082 Have no the measured position arrival signal in parameter specifying area

in automatic tool offset(G36,G37)

083 Specifying an invalid axis or a command is incremental in automatic tool

offset (G36,G37). Modify the program

084 Have the measured position arrival signal in area set by the parameter in

automatic tool offset(G36,G37)

GSK980TDc Turning CNC System User Manual