Nguyễn Văn Thành, KP9 , Chánh Phú Hòa, Bến Cát, Bình Dương

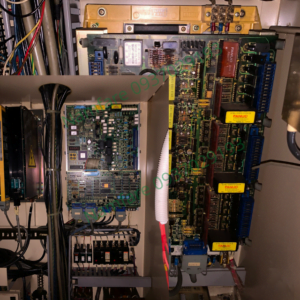

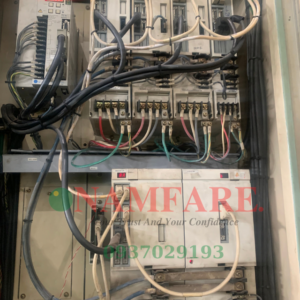

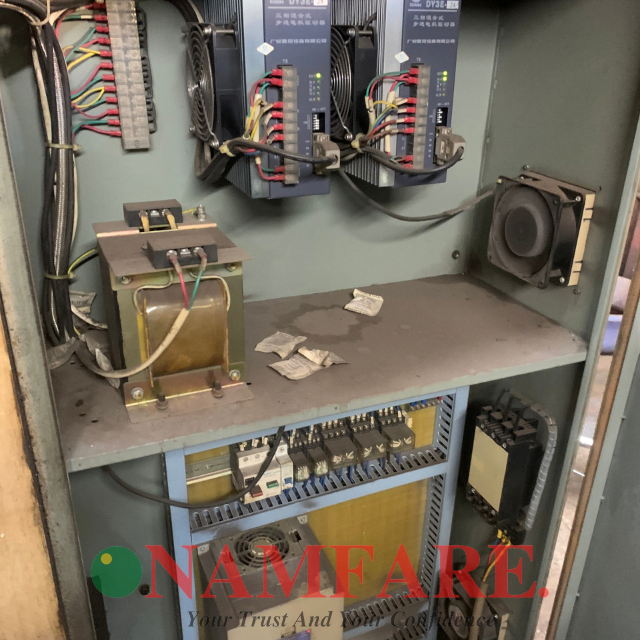

Sửa Máy Cài Đặt Home Máy GSK Home Drive Xinje Reset Drive Maxin

HỖ TRỢ TRỰC TUYẾN

Kinh Doanh: 0937029193

Giờ Làm Việc: 8h đến 18h từ thứ 2 đến thứ 7.

Danh mục: Sửa chữa máy CNC

Mô tả

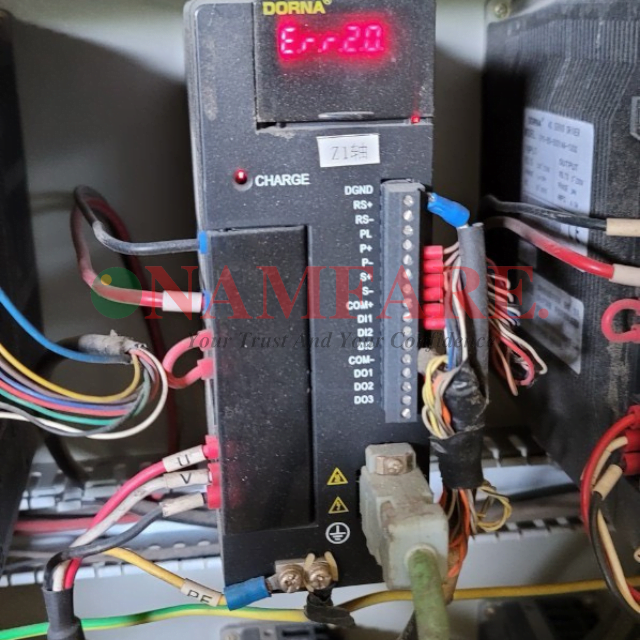

Các drive sau khi hết pin hoặc bị lỗi phải set lại drive, set lại vị trí và set lại máy.

Chúng tôi chuyên reset lại các lỗi của máy chạy hệ điều hành Syntec GSK Tại Bình Dương

PLC alarm(standard PLC ladder definition)

Address Alarm No. Content

A0000.0 1000 Tool change time is too long

A0000.1 1001 Alarm for the tool is not in-position when tool change

ends

A0000.2 1002 Alarm for the tool change is not completed

A0000.3 1003 Alarm for the system has not received the lock signal

A0000.4 1004 The system repetitively checks the lock signal and the

lock signal is invalid when tool change is done

A0000.5 1005 Tool change makes mistakes before the system is turned

off

A0000.6 1006 Pre-indexing proximity switch does not reach

A0000.7 1007 Alarm for tool post overheat

A0001.0 1008 Tailstock function is invalid, and M10 and M11 cannot be

executed

A0001.1 1009 The thread run-out cannot be executed when the spindle

rotating

A0001.3 1011 Have not checked the tailstock forward and cannot start

the spindle

A0001.4 1012 Tool change mode A and B can have up to 8 tools

A0001.5 1013 Tool use life ends

A0001.6 1014 Confirm tool number of tool post (8, 10, 12)

A0001.7 1015 Confirm tool number of tool post (6, 8, 10, 12)

A0002.0 1016 Alarm for protection door not closed

A0002.1 1017 Alarm for pressure low

A0002.3 1019 Can’t release chuck when spindle rotating

A0002.4 1020 Alarm for disabled clamping in-position signal when

spindle rotating

A0002.5 1021 Can’t start spindle when disabled clamping in-position

signal

A0002.6 1022 Can’t start spindle when chuck is released

A0003.0 1024 Can’t execute M12 or M13 with disabled chuck function

A0003.1 1025 Have not checked chuck clamping/releasing in-position

signal

A0003.3 1027 Tool pot is not released or lock signal is not cancelled

A0003.4 1028 Has not found the target tool number

A0003.5 1029 Has not received tool pot stop and locking start signal

A0003.7 1031 Total tools is more than 4, and the external override

cannot be connected (address multiplexing)

A0004.0 1032 Illegal M code

A0004.1 1033 The current spindle is not analog, and Jog function

cannot be executed

A0004.2 1034 M03,M04 specification are mistaken

A0004.3 1035 M63,M64 specification are mistaken

A0004.4 1036 Spindle gear shift time is too long

A0004.5 1037 Spindle speed/position control switch time is too long

GSK980TDc Turning CNC System User Manual

470

Appendix

A0004.6 1038 The 2nd spindle speed/position control switch time is too

long

A0004.7 1039 Spindle position control does not permit orientation

A0005.0 1040 Spindle orientation time is too long

A0005.1 1041 Alarm for the abnormal spindle servo or frequency

converter for abnormality

A0005.2 1042 Alarm for the abnormal 2nd spindle servo or frequency

converter

A0005.3 1043 Forbid clamping the spindle when the spindle rotating or

feeding

A0005.4 1044 Spindle is clamped not to rotate or feed

A0007.0 2000 Hydraulic motor is not started

A0007.1 2001 Safety door has been opened

A0007.3 2003 Alarm for the tool pot unclocked

A0007.5 2005 Regulation is invalid when feedrate override is fixed to

100%

A0007.6 2006 Override on the panel is disabled when external override

is enabled

A0007.7 2007 Program does not run when external pause switch is

OFF

A0008.0 2008 Axis does not move when manual override is 0

Công ty TNHH NAMFARE

MST: 3703122568

Hotline/ Zalo: 0937029193

Email: namfaregroup@gmail.com

Địa chỉ: Thửa đất số 883, tờ bản đồ số 04, đường ĐT741, Khu Phố An Lợi, Phường Hòa Lợi, Thị Xã Bến Cát, Tỉnh Bình Dương, Việt nam

TK: Ngân Hàng ACB, Chi Nhánh Thuận An, Công ty TNHH NAM FARE, STK: 6868976